200L Filling Machine - Quantitative Dispensing Filling System

Product Name

200L Liquid Filling Machine - Quantitative Dispensing System - Corrosive Liquid Filling Equipment

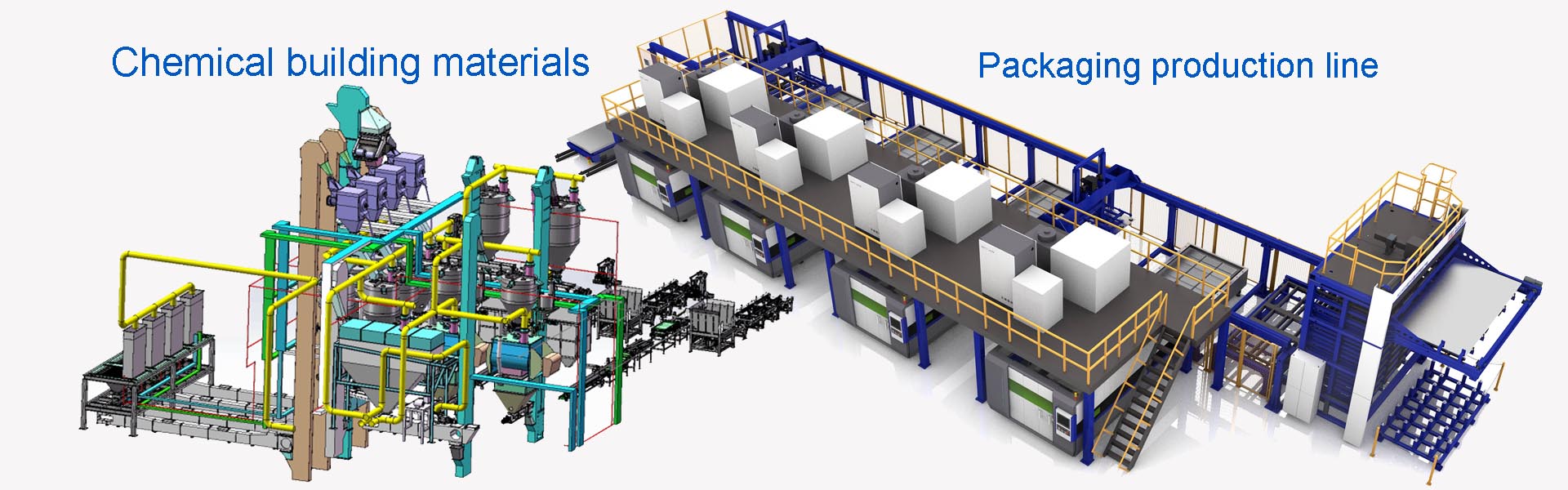

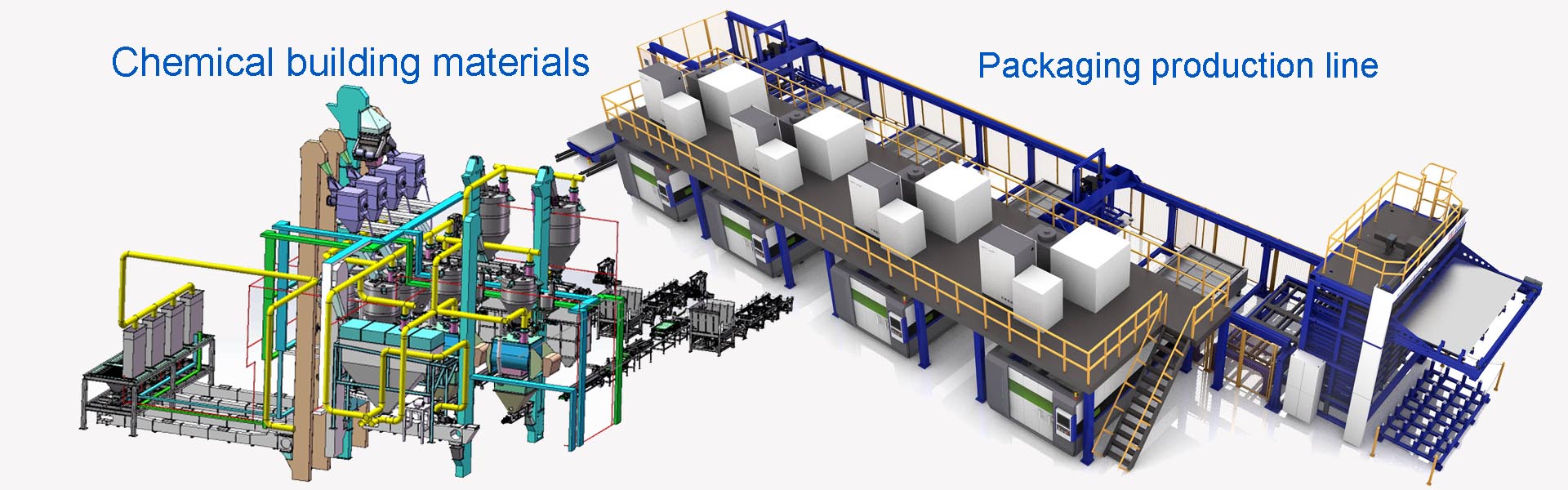

Company Profile

We specialize in automated liquid filling solutions, including semi/full-automatic fillers, paint dispensing scales, electronic scales, load cells, weighing modules, truck scales, and integrated packaging systems. Our products feature premium components such as Toledo weighing modules and controllers for unmatched precision.

Technical Specifications

| Parameter | Details |

|---|---|

| Dispensing Range | 60kg–200kg |

| Max Capacity | 200kg |

| Resolution | 50g |

| Installation | Floor-mounted |

| Color | Shifeng Blue |

| Filling Method | Semi-submerged two-stage filling |

| Accuracy | 0.1% F.S. |

| Material | Carbon steel (powder-coated) + SUS304 stainless steel (contact surfaces) |

| Control System | Semi-automatic liquid-level filling |

| Interlocking Control | Integrated with client’s supply system |

| Feeding Method | Pump-fed front loading |

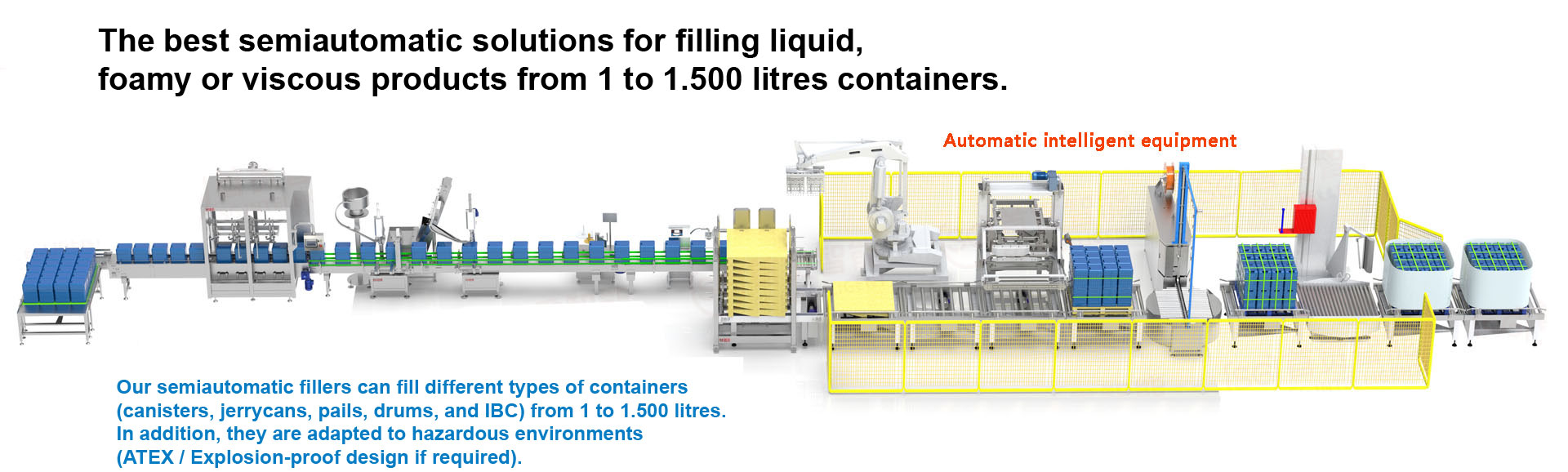

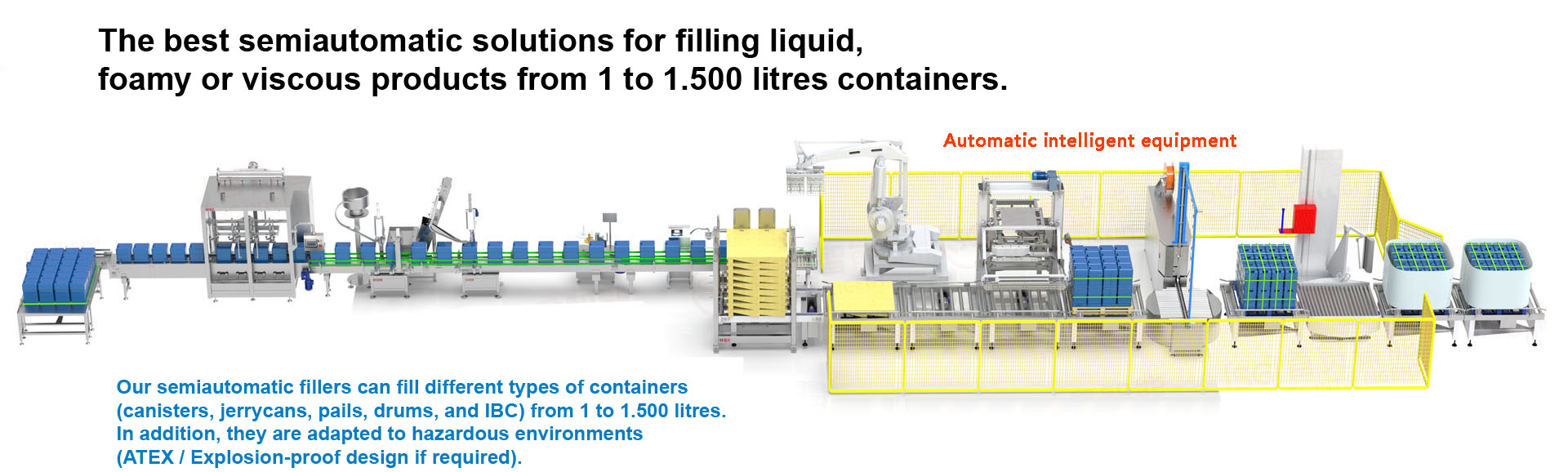

| Explosion-Proof Rating | Exde II BT4 Gb (ATEX compliant) |

| Viscosity Range | 0–10,000 CPS (non-foaming liquids) |

| Speed | 38–42 barrels/hour (200L/min flow rate) |

Key Features

Industrial-Grade Automation:

PLC + touchscreen interface for intuitive operation and preset recipes.

Precision & Safety:

Variable frequency speed control, automatic counting, and "no container, no filling" safety lock.

Durability:

SUS304/316L stainless steel construction, compliant with GMP standards.

Efficient Design:

Turntable positioning system for stable, high-speed filling.

Corrosion Resistance:

Acid-proof materials for harsh chemicals (e.g., hydrochloric acid, solvents).

Operation Workflow

Material Supply:

Auto-refill when tank level drops below the lower limit; stops at upper limit.

Filling Process:

Place empty barrel → Press start → Auto-tare → Insert nozzle → Rapid → Slow filling → Stop at target weight.

Completion:

Nozzle retracts → Display total weight → Manual capping → Remove barrel.

Applications

Chemicals: Polyurethane, polyols, resins, paints, adhesives, curing agents, solvents.

Lubricants & Oils: Engine oil, lubricants, edible oils.

Hazardous Materials: Pesticides, cleaning agents, flammable liquids.