High-Efficiency 25/50kg Lime Powder Packaging Machine for Mortar

Features

Low pollution adopts low air pressure instantaneous flow control. The amount of mixed air during the transportation of materials is very small, and the air pressure is extremely low (about 0.01-0.05Mpa). During the packaging process, bulging, breaking, and material leakage are avoided, effectively controlling the appearance of dust. leakage, effectively reducing the amount of pollution from traditional packaging machines by 70%-90%.

How to operate

The material is added to the weighing hopper by the feeding mechanism (pneumatic gate). After the controller receives the weight signal from the sensor, it controls according to the preset program value. At the beginning, rapid feeding (fast, medium and slow feeding at the same time) is performed. When the weight ≥ (target value - coarse measurement value), stop the fast acceleration signal output and enter the medium speed (medium acceleration and slow acceleration at the same time) feeding; when the weight ≥ (target value - fine measurement value), stop the medium speed Add signal output and enter slow speed (slow adding) feeding; when the weight ≥ (target value - overshoot value), stop slow adding signal output, the feeding door is completely closed, and fixed value weighing is completed. After the bag clamping signal is input, the weighing hopper discharge door automatically opens. When the weight ≤ zero setting value, the weighing hopper discharge door automatically closes, and the material bag automatically releases and falls onto the conveyor belt, and is sent to the sewing machine. After sewing the bag, it enters the next process, and at the same time, the controller enters the next control cycle.

Touch screen PLC control

Touch screen, PLC, C3 level load cell, dual 6-bit high-precision weighing controller (sampling speed up to 128 times/second), and frequency converter to ensure filling quality and accuracy

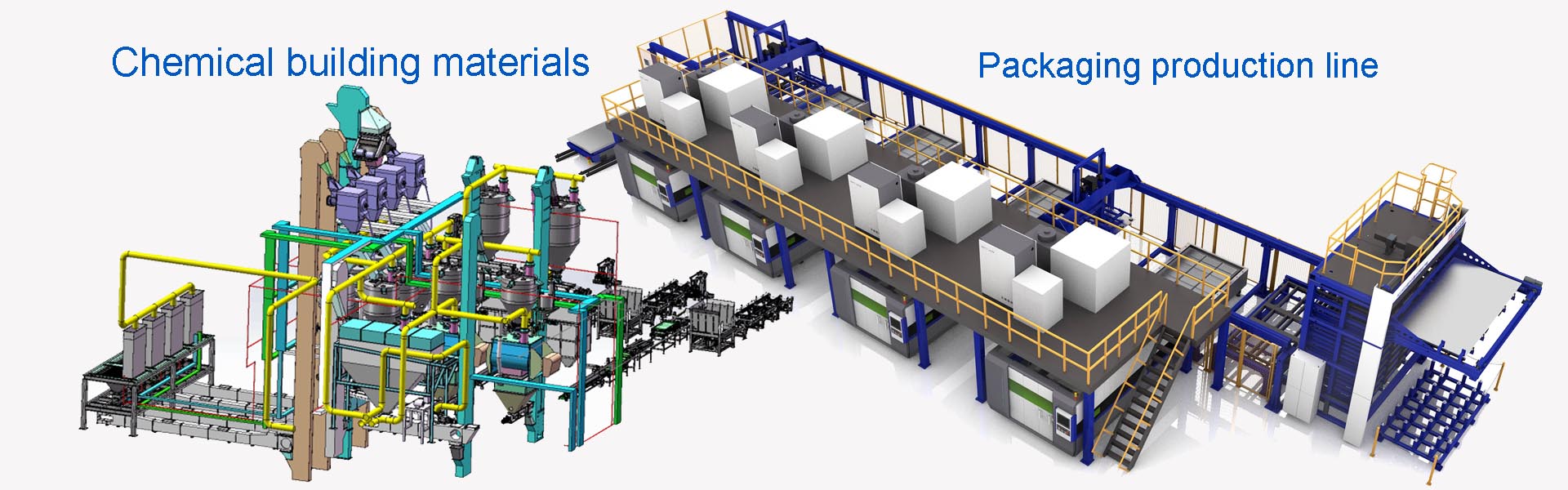

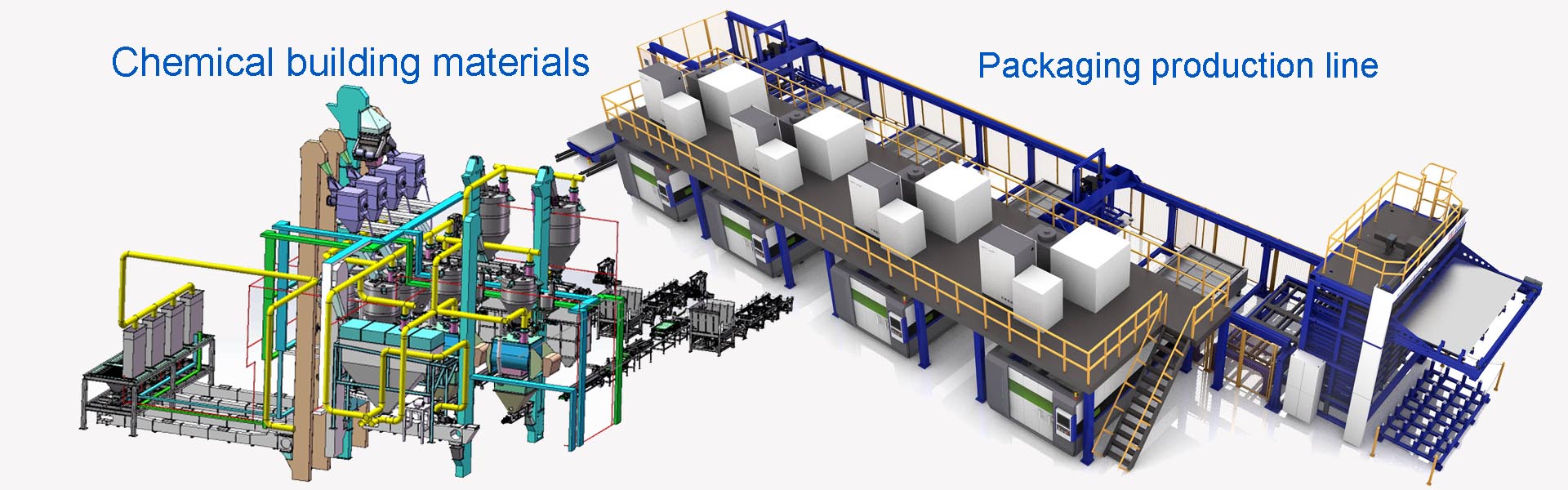

Structure and composition

It is mainly composed of material inlet, feeding mechanism (gate), weighing hopper, bag clamping mechanism, frame, air suction port, pneumatic system, sensor, control box, etc.

-

Silica Fume Powder packaging machine Manufacturing factory[2025-07-03]

-

Sesame Paste packaging machine What is the scope of application[2025-06-30]

-

5kg 10kg 20kg 25kg 30kg 50kg Wheat Flour Corn Starch Weighing Sewing Bag Automatic Packing Filling Machines Powder[2025-06-04]

-

25kg valve bag Mortar Pigments packaging machine Solutions[2025-07-01]